Tapping MACHINES TR SERIES

Prakash Engitech Pvt Ltd is leading Manufacturers and Exporters of tapping Machine TR Series.

Servo Tapping Machines :

- 3 Phase Mitsubishi System

High Torque at High Speed and Smart Power Saver

- High Speed 900-900 / 450-450

/ 300-450 RPM

Stepless Speed with different settings for forward and reverse RPMs

- Mitsubishi Controller & Drives

For Tapping, High Load carrying Controller devices & Drives are Used

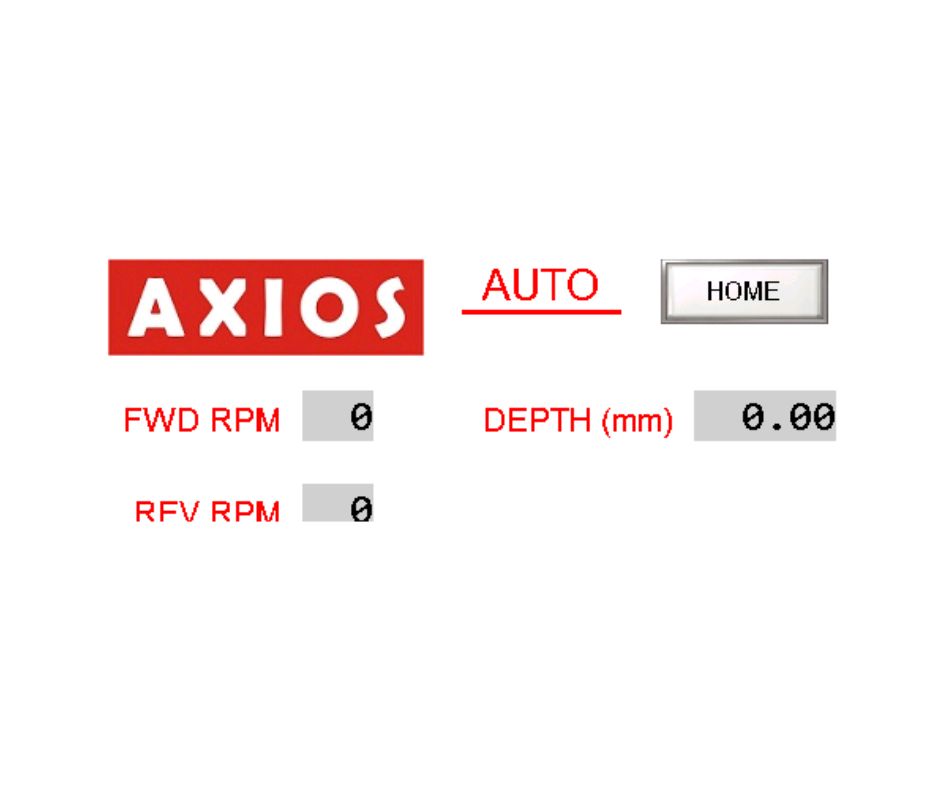

- TouchScreen

Pro – Face Schneider Or Delta make

Servo Tapping Machines

Heavy and sturdy table

Fabricated Table from 4mm Thick plates and angles for resting and mounting of heavy weight jobs upto 600Kg. Mitsubishi

Mitsubishi 3 phase Servo Motor

3 phase motor + double capacity KW in high speed machine then standard single phase machine.

3 Phase 440 V – 220 V Transformer

To sustain power fluctuation upto ± 60 V machine can work smoothly. And also safe PLC Drive & motors.

Mitsubishi PLC

Which can work in temperature upto 55º C.

Electrical Safety

Premium Brands of electricals used with isolation TRANSFORMER

Panel designed to fully cover to safeguard from any impact damage

Bearing Supported Hinges

All pipes and joints supported with bearings for easiest movement and long life.

NO LUBRICATION REQUIRED

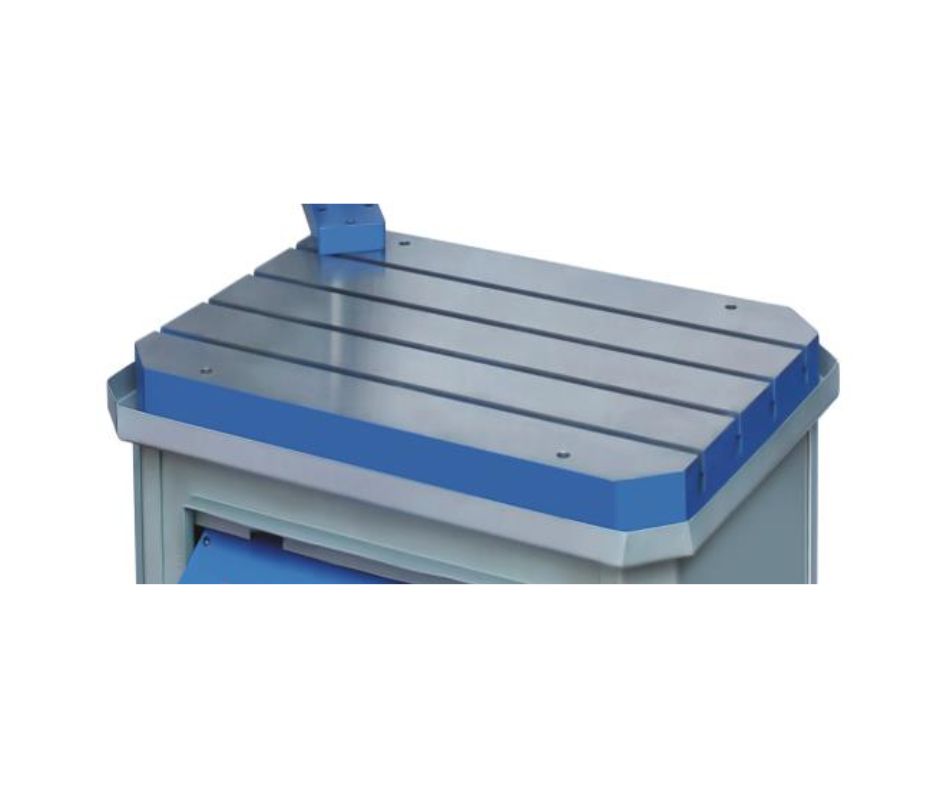

Casting Base with T-Slots

High Precision gound casting base and machined T-Slots

Standard Quick Change Adaptors

Easily and commonly available standard Quick change Chuck and Adaptors

Auto Depth Control

Programmed Depth control with

Manual / Auto / Peck Cycles with option of LH / RH and Pitch / TPI.

360° Universal Head

Heavy-duty special Aluminium grade Universal head that can be set at any angle for horizontal or inclined tapping

Arm Joint Plates

Made of 12 MM thickness for more rigidity.

Heavy Frame Size Planetary GearBox

Heavy duty gearbox with torque rating more than required NM.

* (EA) = Extra Accessories

Description | 12900TR | 16450TR | 24300TR | 33300TR |

Working Radius | 1700 | 1700 | 1700 | 1700 |

No. of Arms | 3 | 3 | 3 | 3 |

Tap Pitch Capacity | 1.75 mm | 2 mm | 3 mm | 3.5 mm |

RPM (FWD / REV) | 0-900/900 | 0-450/450 | 0-300/450 | 0-300/300 |

Tapping Size (MS, EN8D, EN19) | M3-12 mm | M4-16 mm | M4-24 mm | M6-33 mm |

Tapping Size (SS) | M3-10 mm | M4-12 mm | M4-16 mm | M6-22 mm |

Tapping Head Movement | 360° Universal | 360° Universal | 360° Universal | 360° Universal |

Servo Motor | ||||

Servo Drive | ||||

PLC | ||||

Servo Motor | High Speed & High Torque | High Speed & High Torque | High Speed & High Torque | High Speed & High Torque |

Servo Motor Power Input | 3 Phase | 3 Phase | 3 Phase | 3 Phase |

Servo Motor Power | 750 w | 1000 w | 1500 w | 2000 w |

HMI (Touch Screen) | Pro-face (Schneider) orDelta make | Pro-face (Schneider) orDelta make | Pro-face (Schneider) orDelta make | Pro-face (Schneider) orDelta make |

Power Safety | Transformer (440-220) | Transformer (440-220) | Transformer (440-220) | Transformer (440-220) |

Gear Box | Taiwanese | Taiwanese | Taiwanese | Taiwanese |

Hinge Support Plate Thickness | 12mm | 12mm | 12mm | 12mm |

Hinge Bearing Support | INA Germany | INA Germany | INA Germany | INA Germany |

Colour | Powder Coating | Powder Coating | Powder Coating | Powder Coating |

Program Cycle | Manual/Auto/Peck | Manual/Auto/Peck | Manual/Auto/Peck | Manual/Auto/Peck |

(EA ) Working Base | Ground &Machined T Slot | Ground &Machined T Slot | Ground &Machined T Slot | Ground &Machined T Slot |

(EA)Base Size | 800 x 550 | 800 x 550 | 800 x 550 | 800 x 550 |

(EA) Table Size | 850 x 600 x 800 | 850 x 600 x 800 | 850 x 600 x 800 | 850 x 600 x 800 |

Tapping Chuck Size | 1 | 2 | 2 | 3 |

Extra Accessories

Tap Adaptor

Each tap size fits in only one adaptor. This makes it perfectly quick change without changing torque settings and making it perfect tool for each tap.

1 Size = 1 Adaptor

Easily available in a wide range of shank diameter and square sizes. (Refer page No – 6-8)

Please refer/ask for manufacturer’s catalog with list of adaptors

Items Name | Capacity |

KWES 0 B | M1- M10 |

KWES 1 B | M3 – M12 |

KWES 2 B | M8 – M20 |

KWES 3 B | M14 -M33 |

KWES 4 B | M22 – M48 |

Tap Adaptor Reduction Socket

Reduction Socket enables use of all adaptors below size than available chuck size in a machine.

E.g.

KWRE 2/1 – to reduce chuck size from KWES2B to KWES1B making use of KWES1B adaptors in QC2 chuck.

Similarly other available sizes:

KWRE-3/2, KWRE-3/1, KWRE-4/3, KWRE-4/2